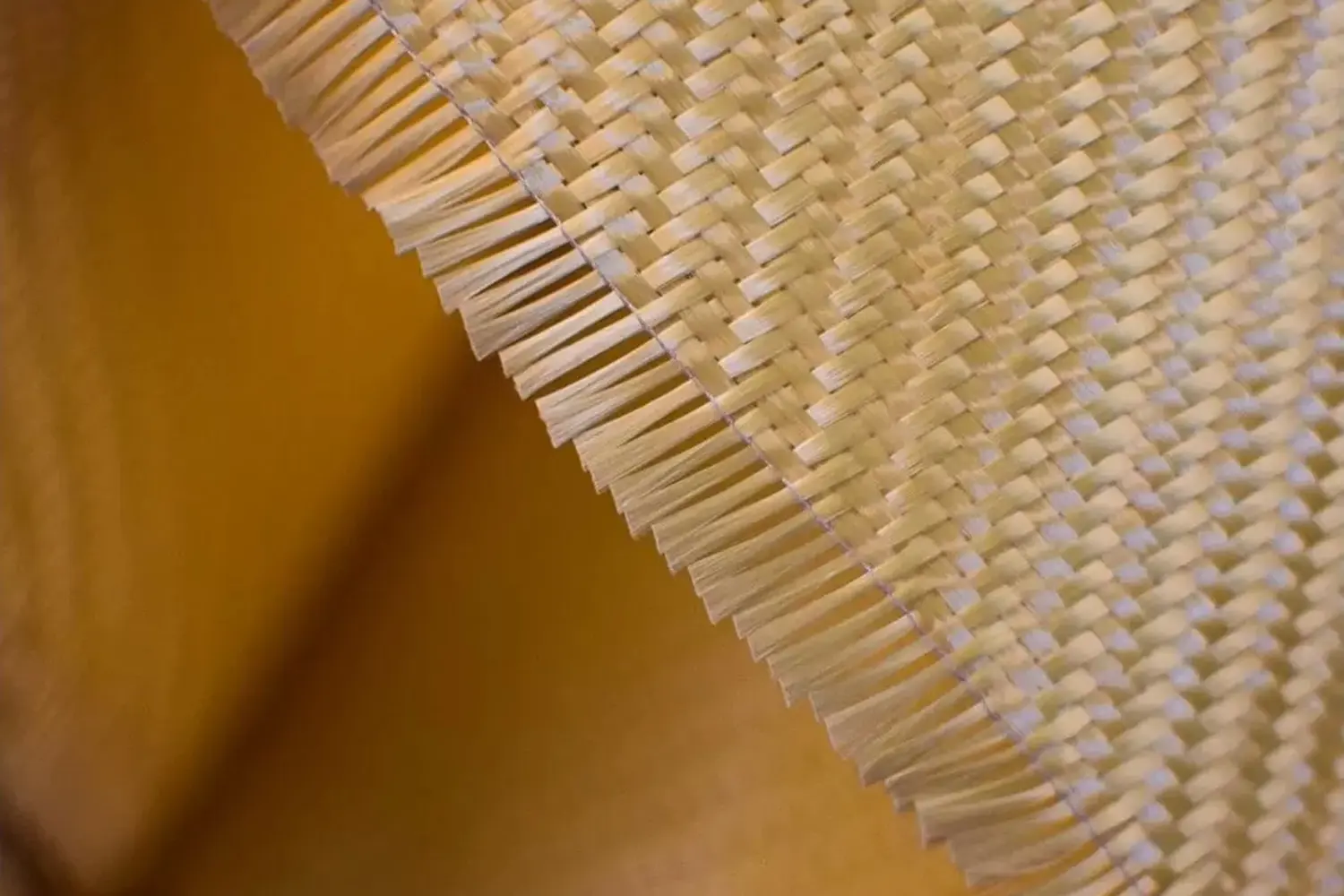

In the innovative sphere of material science, 600D Aramid Fiber(600D Kevlar Fiber) stands out as a transformative element, particularly in the automotive and aerospace sectors. Known for its exceptional thermal properties and high tensile strength, 600D Kevlar Fiber is a pivotal material in advancing the technological capabilities of these industries.

Understanding 600D Aramid Fiber’s Thermal Properties

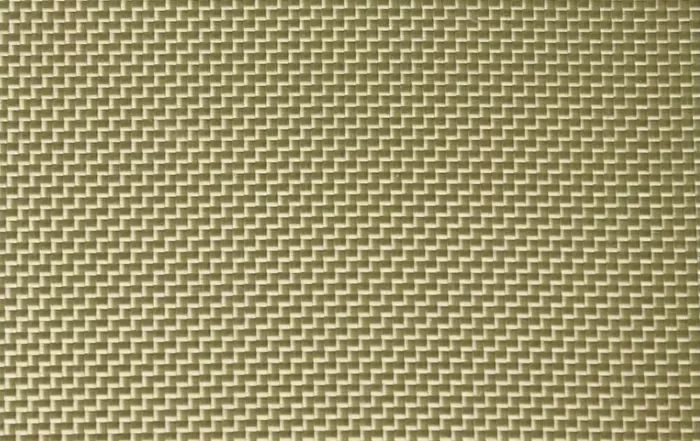

At the core of 600D Kevlar Fiber’s efficacy is its superior thermal performance. Aramid fibers are inherently flame-resistant, meaning they don’t ignite easily. When exposed to extreme heat, 600D Aramid Fiber maintains its integrity without melting or decomposing. This characteristic is crucial in environments where materials are regularly subjected to high temperatures, such as in engine compartments or during atmospheric re-entry in space missions.

The High Tensile Strength of 600D Aramid Fiber

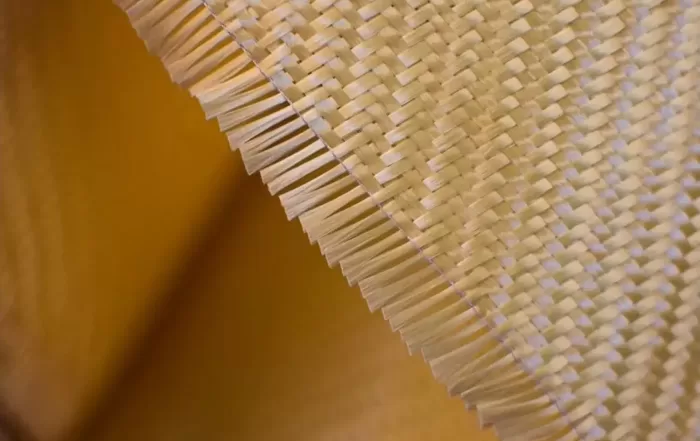

The 600D specification of Kevlar Fiber refers to its density and thickness, which contributes to its high tensile strength. This strength is paramount in applications where durability and resistance to tearing or stretching are essential. The fiber’s robust nature makes it a reliable choice for components that must endure significant stress without compromising on weight or flexibility.

Applications in the Automotive Industry

In the automotive industry, 600D Kevlar Fiber has revolutionized material technology. Its use in tire reinforcements enhances the durability and safety of tires, providing better resistance to heat and wear. This leads to longer tire life and improved performance, particularly in high-speed and demanding driving conditions. Additionally, its heat resistance and strength are beneficial in manufacturing brake pads, where consistent performance under high temperatures is critical.

The integration of 600D Kevlar Fiber into body components of vehicles is another notable application. It offers a lightweight yet strong alternative to traditional materials, thereby improving fuel efficiency and reducing emissions without sacrificing safety or durability.

A Breakthrough in Aerospace Materials

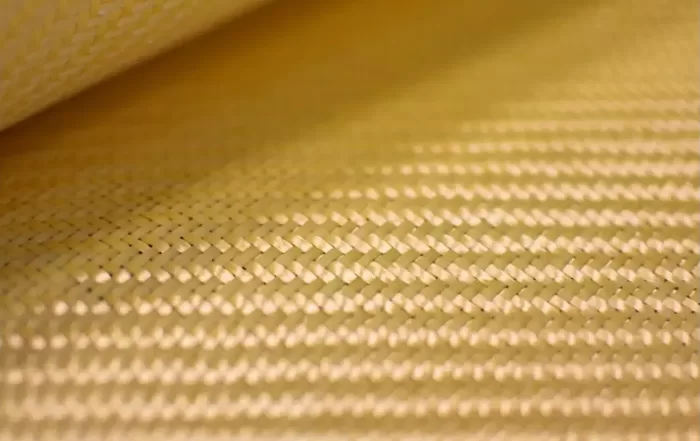

The aerospace industry has witnessed a significant transformation with the incorporation of 600D Kevlar Fiber. Its lightweight and high-strength properties are ideal for various aerospace components, including the construction of airframes and the reinforcement of helicopter blades and fuselage panels. The material’s resistance to fatigue and impact is vital in ensuring the safety and longevity of aerospace vehicles.

In space exploration, 600D Kevlar Fiber plays a critical role in the design of space suits and the thermal insulation of spacecraft. Its ability to withstand extreme temperatures and harsh conditions in space makes it an indispensable material for protecting astronauts and sensitive equipment.

A Material for the Future

The versatility and superior properties of 600D Aramid Fiber make it a material of choice in pushing the boundaries of the automotive and aerospace industries. Its heat resistance, combined with high tensile strength, opens up new possibilities for safer, more efficient, and durable designs. As technological advancements continue, the potential applications of 600D Kevlar Fiber are bound to expand, making it a key component in the evolution of material science.